Technical Report

“Nickel Sulfamate”

A High-Quality Surface Treatment Agent Nickel Sulfamate

-Enabling high-performance plating in diverse applications-

For many years, Nihon Kagaku Sangyo Co., Ltd. (President: KADOYA Hiroki) has been meeting the needs for surface treatment in diverse applications such as electronic components, plastic molding, and electroforming . By leveraging our know-how in surface treatment, we supply nickel sulfamate products, as well as various sulfamate salts and additives, that meet a diverse range of needs.

As information technology (IT) has proliferated in recent years, electronic components in most IT devices have become even more sophisticated and highly integrated. This in turn has led to increasing demands being placed on the performance of surface treatment agents used for such IT devices.

At Nihon Kagaku Sangyo, we supply nickel sulfamate products, as well as various sulfamate salts and additives based on our proprietary core technology for surface treatment. These products, which allow a high degree of control over the plating layer in terms of precision, hardness, and internal stress, are trusted by many of our customers, both domestic and overseas.

【What is nickel sulfamate plating?】

As Owing to its corrosion resistance, nickel is widely used in surface treatment of metal products. Nickel electroplating baths include “Watts bath,” which uses nickel sulfate, and “sulfamic acid bath,” which uses nickel sulfamate. Compared to Watts bath, a sulfamic acid bath using nickel sulfamate, an ionic compound of sulfamic acid and nickel, allows finer plating, and is suited to application in electronic components and precision instruments.

Furthermore, depending on the combination of additives used, a sulfamic acid bath can also be used to control the physical properties of the plating layer, or to lower the environmental impact of electroplating, and consequently, there is an increasing demand for it in a broad range of industries.

・

It enables faster plating than conventional nickel sulfate bath (Watts bath).

・

It has a simple composition, which makes it easier to handle.

・

It has a high water solubility, which enables use at high concentration and application of high current.

・

It forms a plating layer with very low internal stress, which makes it suitable for various electroforming applications such as metal masks and stampers.*1

・

It has a high purity, which enables the formation of very fine electrodeposits (plating layer).*2

・

It is not easily affected by impurities.

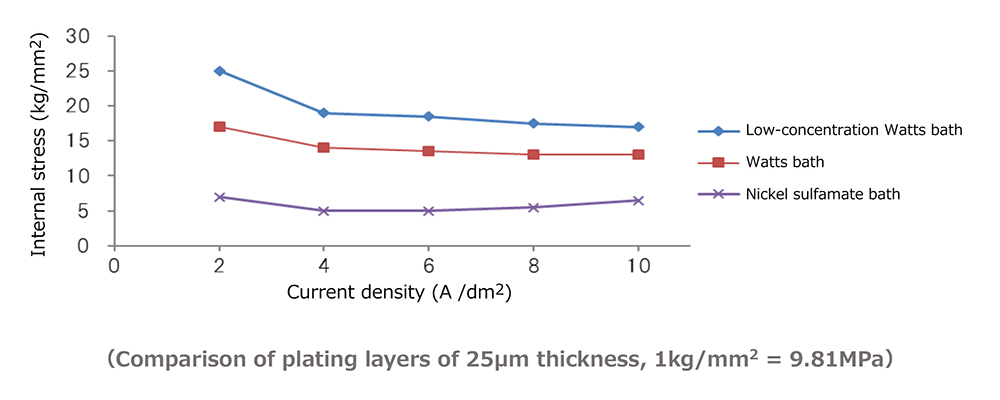

<*1Comparison of current density of plating solutions and internal stress of plating layers>

Compared to Watts bath, nickel sulfamate bath results in a stable internal stress of 10kg/mm² or lower. Furthermore, even if the current density is increased, there is only a small increase in the internal stress, and it is suitable for electroforming that requires precise sizing.

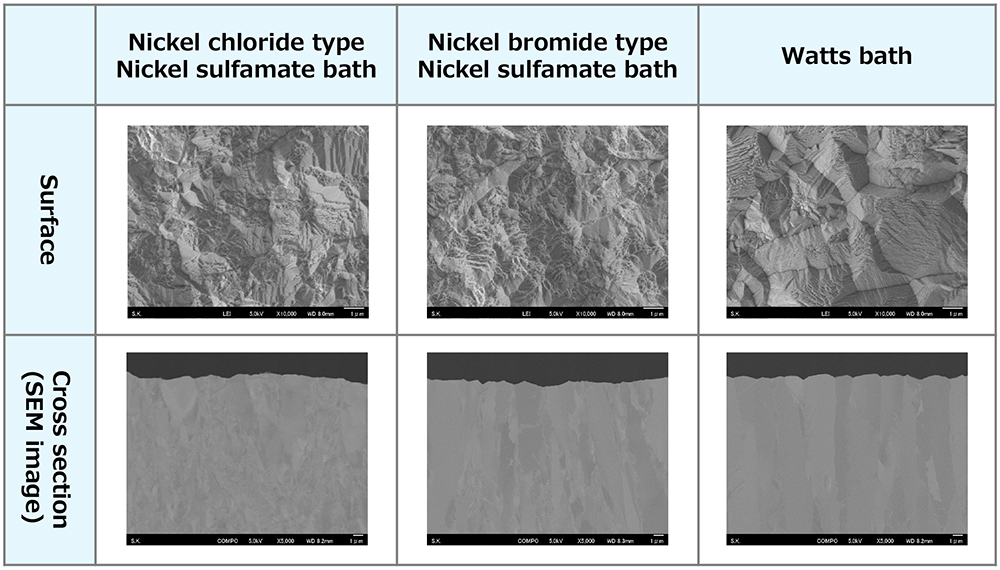

<*2Comparison of the surface and cross section of plating layers>

Due to the high purity of the plating agent, very fine electrodeposits (plating layers) of minute particles can be achieved.

【Advantages of Nihon Kagaku Sangyo’s nickel sulfamate】

Our nickel sulfamate plating products offer the advantages listed below.

・

Enable us to recommend plating agents and technologies suitable for a variety of plating methods (e.g., rack-, barrel -, or hoop plating ; and electroforming)

・

Enable us to recommend a variety of additives that meet our customers’ needs in terms of brightening , alleviating internal stress, and enhancing uniformity of coverage

・

Help customers to maintain high-quality, stable production through a rich product lineup and reliable, prompt technical support

・

Are available as environmentally friendly products

-

―

They are free from boron, which makes the treatment of wastewater easy.

-

―

They do not crystallize at low temperatures, so they can be used in cold climates and during winter.

-

―

They do not require the plating process to be conducted at high temperature, so they can be used with materials that have low heat tolerance, contributing to lowering of carbon footprint.

【Our rich product lineup】

We also supply a wealth of other products such as various sulfamate salts and additives that meet our customers’ requirements in terms of quality. These allow us to meet a diverse range of surface treatment needs. We offer solutions for a broad range of substrate materials and shapes; please do not hesitate to contact us with your inquiries.

<Nickel Sulfamate series>

・

60% Nickel Sulfamate Solution

・

60% Nickel Sulfamate Solution (High purity)

・

65% Nickel Sulfamate Solution

・

Nickel Sulfamate (Crystals)

・

NI-BF process (Boron-free, eco-friendly)

<Sulfamates series>

・

50% Cobalt Sulfamate Solution

・

50% Lithium Sulfamate Solution

・

50% Manganese Sulfamate Solution

・

40% Ferrous Sulfamate Solution

・

35% Indium Sulfamate Solution

<Brighteners/Additives>

・

NSF series (H-1 to 6, E, X) (Brightener)

・

PITLESS S (Pit Prevention Additives)

・

NIKKA NONTACK (Mold releasing agent for electroforming)

・

Ni Activator (Liquid to remove oxide film)

【Stable supply and technical support backed by domestic production】

We develop and produce nickel sulfamate and other superior surface treatment agents within Japan, primarily at our R&D Center and Saitama Plant, thus ensuring the stable supply of our products.

In addition, we developed a system for provision of attentive technical support in conjunction with our other domestic sites. This allows us to meet a diverse range of surface treatment needs. We offer solutions for a broad range of substrate materials and shapes; please do not hesitate to contact us with your inquiries.

The R&D Center takes action according to the customer’s problems and requests, and also evaluates and analyzes our products. For more than 80 years, Nihon Kagaku Sangyo has stood alongside to its customers and assisted them in solving their issues.

Detailed product information and technical information on nickel sulfamate,

can be downloaded from here.