Technical Report

“Electroless Plating”

Development of PFAS-Free Electroless

Composite Plating Technologies

-Use for sliding parts contributes to solving a societal issue-

Nihon Kagaku Sangyo Co., Ltd. (President: KADOYA Hiroki) has been working on the technical development of electroless composite plating that does not contain per- and polyfluoroalkyl substances (PFAS), which are seen as a concern worldwide, especially in the EU, due to their impact on human health and the natural environment. Our efforts in this regard draw on our many years spent developing surface treatment agents and our know-how regarding associated manufacturing technologies. As a result, we succeeded in developing two proprietary electroless composite plating technologies that combine improved performance with being PFAS-free, and filed patent applications for these technologies in 2022 and 2024.

【Background to the development】

Composite plating using polytetrafluoroethylene (PTFE), which is a form of PFAS, generally has a low friction coefficient and superb durability, and it is therefore widely used for sliding parts and similar applications. On the other hand, PFAS have high chemical stability and thus remain and accumulate in the environment for prolonged periods without being decomposed. Consequently, their impact on human health and the natural environment is regarded as a cause for concern and regulation of PFAS is under way around the world. At Nihon Kagaku Sangyo, we had anticipated that PFAS regulation would gain momentum in the near future and have therefore been developing PFAS-free composite plating technologies for some time already, aiming to take the lead in helping to solve the societal issue posed by these substances.

Furthermore, the advancement of technologies in sectors such as automobiles, aerospace, heavy industry, and electronic components, means that the level of performance required from surface treatment agents is increasing. Even in the auto industry, for example, the rapid transition to electric vehicles means such agents are now expected to deliver features such as minimal environmental impact as well as the functionality required for these vehicles’ sliding parts.

We therefore decided to take our proprietary surface treatment technologies further to respond to these needs by developing electroless composite plating technologies combining improved performance and PFAS-free.

【What is the core technology underlying PFAS-free composite plating?】

For many years, we have been meeting needs for surface treatment in diverse applications such as electronic components, plastic molding, and electroforming by supplying various raw materials for plating solutions and chemicals for electroless plating, alongside developing plating processes. The resulting know-how relating to metal salts (primarily nonferrous) provided the basis for us to take on the development of technologies that would address both the societal issue of eliminating PFAS and the manufacturing community’s demands for improved performance.

As a result of exploring the options, we succeeded in selecting composite materials to replace PTFE and developing a core technology to disperse and stabilize those materials. This technology can be used without any new capital investment by customers currently engaged in PTFE composite plating.

The new core technology means that PFAS-free composite plating can not only be used as a substitute for PTFE composite plating, but also offers wide-ranging potential in applications where use of PTFE composite plating has proved difficult in the past.

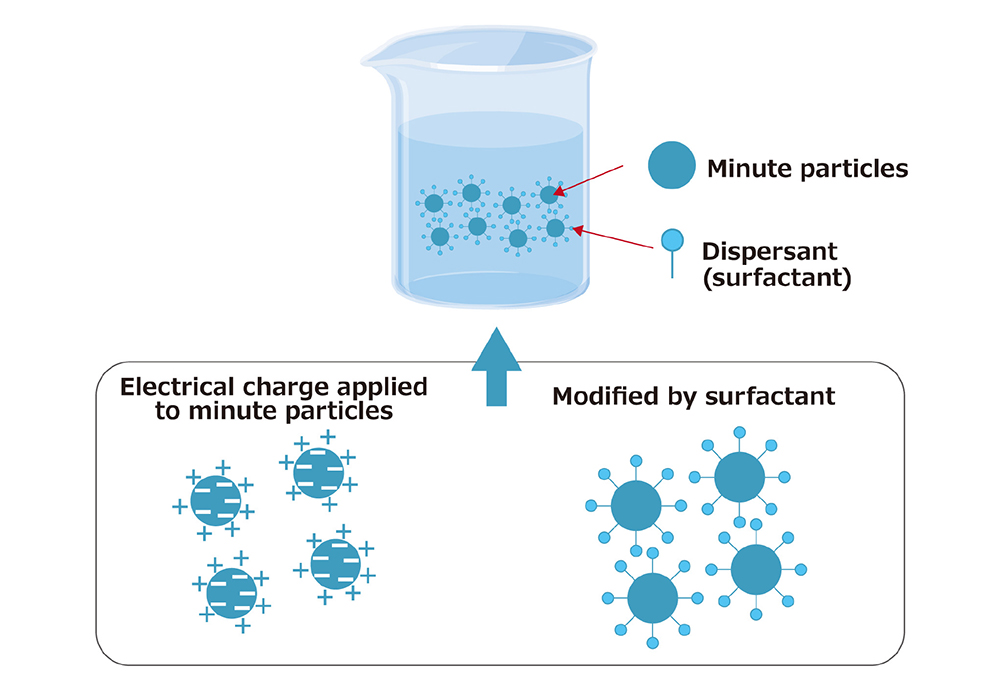

<Core techology>Minute particle distribution technology

The co-deposition of minute particles of substances such as the new resin powder and mica in the plating coat make it possible to impart characteristics such as sliding performance, hardness, and abrasion resistance that cannot be obtained by metal coating alone.

This is where our proprietary minute particle distribution technology—which controls the surface condition of the minute particles—comes into play.

・

Technology that optimizes condition of minute particles via co-deposition

・

Technology that produces optimal surface charge and particle size distribution

<Key features of our two new plating technologies>

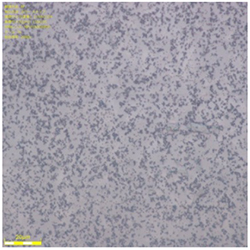

Technology using new resin powder as the composite material

・

We drew on our proprietary know-how regarding particle distribution and use of co-deposition in plating to add a resin powder that easily forms a composite with the plating solution and performs well.

・

We produced a plating coat offering the same level of hydrophobicity and low friction as PTFE composite plating.

・

Unlike a PTFE composite plating coat, the new plating is oleophilic, which allows it to work well with lubricant oil. It can therefore be used together with lubricant oil, making it suitable for sliding parts and other components that require such oil.

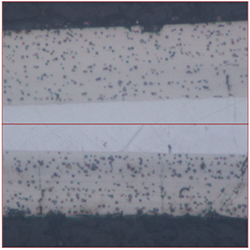

Plating surface

Cross section

- 【Anticipated needs】

・

Use for sliding parts requiring lubricity even in oily environments

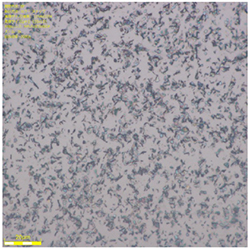

Technology using mica as the composite material

・

Use of mica enabled us to simultaneously solve several issues that posed problems with regard to PTFE composite plating, such as the difficulty associated with chemical liquid control during the manufacturing process and when handling plating solutions, and the use of large volumes of surfactant.

・

Unlike with PTFE composite plating, no surfactant is required, making it possible to maintain high abrasion resistance while reducing the friction coefficient. This allows mica-based composite plating to be used for applications requiring low friction.

・

One of the distinctive features of mica as a solid lubricant is its high seizure resistance, which gives it outstanding lubricity in environments where the surface pressure is high.

Plating surface

Cross section

- 【Anticipated needs】

・

Use for sliding parts requiring a very hard plating coat and seizure resistance

<Summary of technical features>

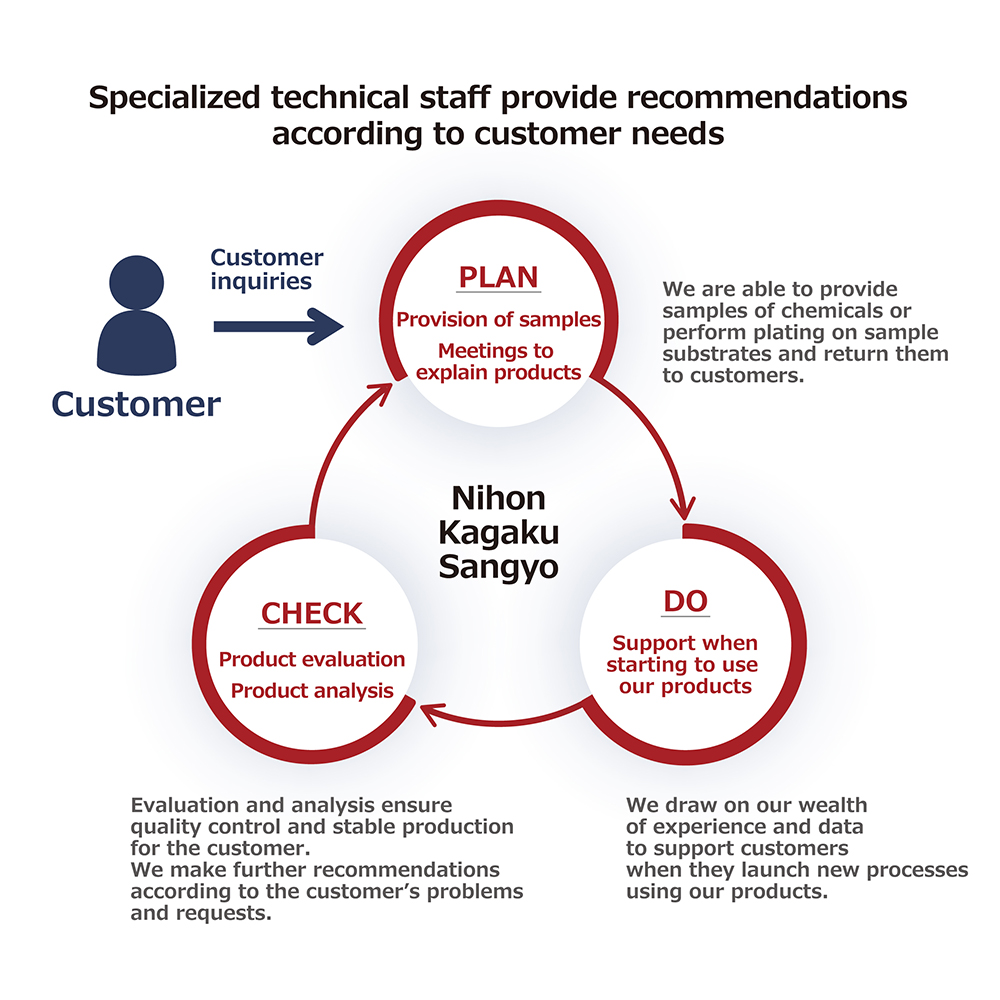

【Attentive technical support system】

We develop characteristic surface treatment agents at our R&D Center and operate an attentive technical support system. This system allows us to offer solutions that meet a diverse range of surface treatment needs, including PFAS-free composite plating, and are suitable for a broad range of substrate materials and shapes. Please do not hesitate to contact us with your inquiries.

Detailed product information and technical information on Electroless Plating,

can be downloaded fromhere.